Nissan Sentra Service Manual: Cooler pipe and hose

Exploded view

- High-pressure service port

- High-pressure pipe

- Expansion valve

- Low-pressure service port

- Low-pressure flexible hose

- Compressor

- Refrigerant pressure sensor

- Condenser and liquid tank assembly

- High-pressure flexible hose

Low-pressure flexible hose

Low-pressure flexible hose : removal and installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

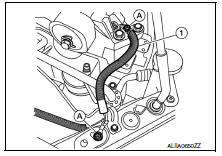

- Remove the upper torque rod bolts (A) and the upper torque rod (1).

- Remove the washer tank inlet bolt (A), then pull the washer tank inlet (1) up and out of the washer tank.

- Remove the engine ground bolts (A) and the engine ground (1).

- Remove the A/C pipe bracket bolts (A).

(1): Low-pressure service port

(2): High-pressure service port

- Remove the push nut (A) from the expansion valve insulator (1) and reposition.

- Remove the bolt (A) that retains the high-pressure pipe and lowpressure flexible hose to the expansion valve, then disconnect the low-pressure flexible hose from the expansion valve and high-pressure pipe.

CAUTION:

Cap or wrap the joint of the hose with suitable material such as vinyl tape to avoid the entry of air.

- Remove the front under cover. Refer to EXT-31, "ENGINE UNDER COVER : Removal and Installation".

- Remove the bolt that retains the high-pressure flexible hose to the compressor, then disconnect the highpressure flexible hose from the compressor.

- Remove the bolt that retains the low-pressure flexible hose to the compressor, then disconnect the lowpressure flexible hose from the compressor.

- Remove the low-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to the new O-rings.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

High-pressure flexible hose

High-pressure flexible hose : removal and installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove the core support upper cover. Refer to HA-39, "Exploded View".

- Remove the bolt (A) that retains the high-pressure flexible hose to the condenser, then disconnect the high-pressure flexible hose from the condenser and liquid tank assembly.

CAUTION:

Cap or wrap the joint of the hose with suitable material such as vinyl tape to avoid the entry of air.

- Remove the bolt that retains the high-pressure flexible hose to the compressor, then disconnect the highpressure flexible hose from the compressor.

- Remove the high-pressure flexible hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to new O-rings.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

High-pressure pipe

High-pressure pipe : removal and installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove the core support upper. Refer to HA-39, "Exploded View".

- Remove the low-pressure flexible hose. Refer to HA-35, "LOW-PRESSURE FLEXIBLE HOSE : Removal and Installation".

- Remove the bolt (A) that retains the high-pressure pipe to the condenser, then disconnect the high-pressure pipe from the condenser and liquid tank assembly.

CAUTION:

Cap or wrap the joint of the pipe with a suitable material such as vinyl tap to avoid the entry of air.

- Remove the high-pressure pipe.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-rings.

- Apply A/C oil to new O-rings.

- After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test".

Compressor

Compressor

Exploded view

With air conditioning

Compressor

Front

Without air conditioning

A/c idler pulley

A/c idler pulley bracket

Compressor

Compressor : removal and installation

REM ...

Condenser

Condenser

Exploded view

Core support upper cover

High-pressure pipe

High-pressure flexible hose

Refrigerant pressure sensor

Condenser and liquid tank assembly

Core support upper

Front

Conde ...

Other materials:

Water pump

Exploded View

Gasket

Water pump

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns

could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap.

Slowly push down and

turn it a quarter turn to allow built-up ...

Maintenance requirements

Your NISSAN has been designed to have minimum

maintenance requirements with long service

intervals to save you both time and money;

however, some day-to-day and regular maintenance

is essential to maintain your NISSAN’s

good mechanical condition as well as its emissions

and engine performanc ...

M&A branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the combination meter for damage,

bend and loose connection

(unit side and connector side).

Is the inspection result nor ...