Nissan Sentra Service Manual: Power supply and ground circuit

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-51, "Wiring Diagram".

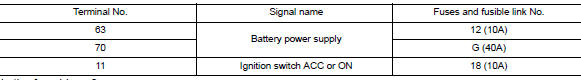

1.Check fuses and fusible link

Check that the following fuses and fusible link are not blown.

Is the fuse blown? Yes >> replace the blown fuse or fusible link after repairing the affected circuit.

No >> go to 2.

2.Check power supply circuit

- Disconnect BCM connector M85.

- Check voltage between BCM connector M85 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> repair harness or connector.

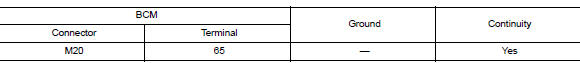

3.Check ground circuit

Check continuity between bcm connector m85 and ground.

Is the inspection result normal? Yes >> inspection end.

No >> repair harness or connector.

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITHOUT INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding wiring diagram information, refer to bcs-111, "wiring diagram".

1.Check fuses and fusible link

Check that the following fuses and fusible link are not blown.

Is the fuse blown? Yes >> replace the blown fuse or fusible link after repairing the affected circuit.

No >> go to 2.

2.Check power supply circuit

- Turn ignition switch OFF.

- Disconnect BCM connectors.

- Check voltage between bcm connector and ground.

Is the inspection result normal? Yes >> go to 3.

No >> repair harness or connector.

3.Check ground circuit

Check continuity between bcm connector and ground.

Is the inspection result normal? Yes >> inspection end.

No >> repair harness or connector.

POWER WINDOW MAIN SWITCH

POWER WINDOW MAIN SWITCH : Description

- Bcm supplies power.

- It operates each power window motor via corresponding power window switch and makes window move up/ down when main power window and door lock/unlock switch is operated.

POWER WINDOW MAIN SWITCH : Component Function Check

Main power window and door lock/unlock switch

1. Check main power window and door lock/unlock switch function

Check power window motor operation with main power window and door lock/unlock switch.

Is the inspection result normal? YES >> Main power window and door lock/unlock switch power supply and ground circuit are OK.

NO >> Refer to PWC-33, "POWER WINDOW MAIN SWITCH : Diagnosis Procedure".

POWER WINDOW MAIN SWITCH : Diagnosis Procedure

Regarding wiring diagram information, refer to pwc-18, "wiring diagram".

Main power window and door lock/unlock switch power supply circuit check

1. Check power supply circuit

- Turn ignition switch ON.

- Check voltage between main power window and door lock/unlock switch connectors D5, D11 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> go to 2.

2. Check harness continuity

- Turn ignition switch off.

- Disconnect bcm, main power window and door lock/unlock switch, power window and door lock/unlock switch rh, rear power window switch lh and rear power window switch rh.

- Check continuity between bcm connector and main power window and door lock/unlock switch connectors.

- Check continuity between bcm connector m85 or m20 and ground.

Is the inspection result normal? Yes >> go to 4.

No >> repair or replace the harness or connectors.

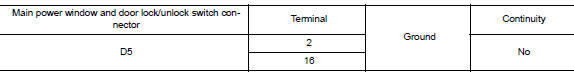

3. Check ground circuit

- Turn ignition switch off.

- Disconnect main power window and door lock/unlock switch.

- Check continuity between main power window and door lock/unlock switch connector d11 and ground.

Is the inspection result normal? Yes >> check main power window and door lock/unlock switch output signal (rear power window switch lh) go to 5.

Yes >> check main power window and door lock/unlock switch output signal (rear power window switch rh) go to 6.

Yes >> check main power window and door lock/unlock switch output signal (front power window switch lh) go to 7.

Yes >> check main power window and door lock/unlock switch output signal (front power window switch rh) go to 8.

No >> repair or replace the harness or connectors.

4. Check bcm output signal

- Connect bcm.

- Turn ignition switch ON.

- Check voltage between BCM connector M85 or M20 and ground.

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace bcm. Refer to bcs-73, "removal and installation" (with intelligent key) or bcs-126, "removal and installation" (without intelligent key).

5. Check main power window and door lock/unlock switch output signal (rear power window switch lh)

- Connect main power window and door lock/unlock switch.

- Turn ignition switch on.

- Check voltage between main power window and door lock/unlock switch d5 and ground.

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace main power window and door lock/unlock switch. Refer to pwc-70, "removal and installation".

After that, refer to pwc-29, "work procedure".

6. Check main power window and door lock/unlock switch output signal (rear power window switch rh)

- Connect main power window and door lock/unlock switch.

- Turn ignition switch ON.

- Check voltage between main power window and door lock/unlock switch d5 and ground.

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace main power window and door lock/unlock switch. Refer to pwc-70, "removal and installation".

After that, refer to pwc-29, "work procedure"

7. Check main power window and door lock/unlock switch output signal (front power window switch lh)

- Connect main power window and door lock/unlock switch.

- Turn ignition switch ON.

- Check voltage between main power window and door lock/unlock switch d11 and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace main power window and door lock/unlock switch. Refer to PWC-70, "Removal and Installation".

After that, refer to PWC-29, "Work Procedure".

8. Check main power window and door lock/unlock switch output signal (front power window switch rh)

- Connect main power window and door lock/unlock switch.

- Turn ignition switch ON.

- Check voltage between main power window and door lock/unlock switch D5 and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace main power window and door lock/unlock switch. Refer to PWC-70, "Removal and Installation".

After that, refer to PWC-29, "Work Procedure".

POWER WINDOW MAIN SWITCH : Component Inspection

1. Check main power window and door lock/unlock switch

- Check main power window and door lock/unlock switch D5.

- Check continuity between main power window and door lock/unlock switch d5 (power window lock switch) (lock operation).

- Check continuity between main power window and door lock/unlock switch d5 (power window lock switch) (unlock operation).

Is the inspection result normal? YES >> Main power window and door lock/unlock switch is OK.

NO >> Replace main power window and door lock/unlock switch. Refer to PWC-70, "Removal and Installation".

After that, refer to PWC-29, "Work Procedure".

POWER WINDOW MAIN SWITCH : Special Repair Requirement

1. Perform initialization procedure

Perform initialization procedure.

Refer to pwc-29, "work procedure".

Is the inspection result normal? Yes >> go to 2.

No >> check intermittent incident. Refer to gi-39, "intermittent incident".

2. Check anti-pinch operation

Check anti-pinch operation.

Refer to pwc-30, "work procedure".

Is the inspection result normal? Yes >> inspection end.

No >> refer to pwc-32, "power window main switch : component function check".

FRONT POWER WINDOW SWITCH

FRONT POWER WINDOW SWITCH : Description

- Bcm supplies power.

- Front power window motor RH will be operated if power window and door lock/unlock switch RH is operated

FRONT POWER WINDOW SWITCH : Component Function Check

Power window and door lock/unlock switch rh

1. Check power window motor function

Check front power window motor operation with power window and door lock/unlock switch rh.

Is the inspection result normal? Yes >> power window and door lock/unlock switch rh power supply and ground circuit are ok.

No >> refer to pwc-37, "front power window switch : diagnosis procedure".

FRONT POWER WINDOW SWITCH : Diagnosis Procedure

Regarding Wiring Diagram information, refer to PWC-18, "Wiring Diagram".

Power window and door lock/unlock switch rh power supply circuit check

1. Check power supply circuit (power window and door lock/unlock switch rh)

- Turn ignition switch ON.

- Check voltage between power window and door lock/unlock switch rh connector d104 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2. Check harness continuity

- Turn ignition switch OFF.

- Disconnect bcm, power window and door lock/unlock switch rh, rear power window switch lh and rear power window switch rh.

- Check continuity between bcm connector m85 or m20 and power window and door lock/unlock switch rh connector d104.

- Check continuity between bcm connector m85 or m20 and ground.

Is the inspection result normal? Yes >> go to 4.

No >> repair or replace the harness or connectors.

3. Check harness continuity (power window and door lock/unlock switch rh)

- Turn ignition switch off.

- Disconnect main power window and door lock/unlock switch and power window and door lock/unlock switch rh.

- Check continuity between main power window and door lock/unlock switch connector D5 and power window and door lock/unlock switch RH connector D104.

- Check continuity between main power window and door lock/unlock switch connector d5 and ground.

Is the inspection result normal? Yes >> go to 5

No >> repair or replace the harness or connectors.

4. Check bcm output signal

- Connect BCM.

- Turn ignition switch on.

- Check voltage between bcm connector m85 or m20 and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace BCM. Refer to BCS-73, "Removal and Installation" (with Intelligent Key) or BCS-126, "Removal and Installation" (without Intelligent Key).

5. Check power window and door lock/unlock switch rh

Check power window and door lock/unlock switch rh.

Refer to pwc-39, "front power window switch : component inspection".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace power window and door lock/unlock switch rh. Refer to pwc-71, "removal and installation".

FRONT POWER WINDOW SWITCH : Component Inspection

Component inspection

1. Check power window and door lock/unlock switch rh

Check power window and door lock/unlock switch rh d104.

Is the inspection result normal? Yes >> power window and door lock/unlock switch rh is ok.

No >> replace power window and door lock/unlock switch rh. Refer to pwc-71, "removal and installation".

REAR POWER WINDOW SWITCH

REAR POWER WINDOW SWITCH : Description

- BCM supplies power.

- Rear power window motor will be operated if rear power window switch is operated. Rear power window switch.

REAR POWER WINDOW SWITCH : Component Function Check

Rear power window switch

1. Check rear power window motor function

Check rear power window motor operation with rear power window switch.

Is the inspection result normal? Yes >> rear power window switch power supply and ground circuit are ok.

No >> refer to pwc-40, "rear power window switch : diagnosis procedure".

REAR POWER WINDOW SWITCH : Diagnosis Procedure

Regarding wiring diagram information, refer to pwc-18, "wiring diagram".

Rear power window switch power supply circuit check

1. Check power supply circuit

- Turn ignition switch ON.

- Check voltage between rear power window switch connector d203 or d303 and ground.

Is the inspection result normal? Yes >> go to 2 (rear power window switch lh).

Yes >> go to 3 (rear power window switch rh).

No >> go to 4.

Is the inspection result normal? Yes >> go to 2 (rear power window switch lh).

Yes >> go to 3 (rear power window switch rh).

No >> go to 4.

2. Check harness continuity (rear power window switch lh)

- Turn ignition switch off.

- Disconnect main power window and door lock/unlock switch and rear power window switch LH.

- Check continuity between main power window and door lock/unlock switch connector D5 and rear power window switch LH connector D203.

- Check continuity between main power window and door lock/unlock switch connector d5 and ground.

Is the inspection result normal? Yes >> go to 5.

No >> repair or replace the harness or connectors.

3. Check harness continuity (rear power window switch rh)

- Turn ignition switch off.

- Disconnect main power window and door lock/unlock switch and rear power window switch rh.

- Check continuity between main power window and door lock/unlock switch connector d5 and rear power window switch rh connector d303.

- Check continuity between main power window and door lock/unlock switch connector D5 and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace the harness or connectors.

4. Check harness continuity

- Disconnect bcm, power window and door lock/unlock switch rh, rear power window switch lh and rear power window switch rh.

- Check continuity between BCM connector and rear power window switch connector.

- Check continuity between BCM connector M85 or M20 and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-73, "Removal and Installation" (with Intelligent Key) or BCS-126, "Removal and Installation" (without Intelligent Key).

NO >> Repair or replace harness or connectors.V

5. Check rear power window switch

Check rear power window switch.

Refer to pwc-42, "rear power window switch : component inspection".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace rear power window switch. Refer to pwc-72, "removal and installation".

REAR POWER WINDOW SWITCH : Component Inspection

Component inspection

1. Check rear power window switch

Check rear power window switch.

Is the inspection result normal? YES >> Rear power window switch is OK.

NO >> Replace rear power window switch. Refer to PWC-72, "Removal and Installation".

Power window motor

Power window motor

DRIVER SIDE

DRIVER SIDE : Description

Door glass moves up/down by receiving the signal from main power window and

door lock/unlock switch

DRIVER SIDE : Component Function Check

1. Check front po ...

Other materials:

Battery saver output/power supply circuit

Description

Provides the battery saver output/power supply. Also cuts the power supply

when the interior lamp battery

saver is activated.

Component function check

1.Check battery saver output/power supply function

Consult

Turn ignition switch on.

Turn each interior lamp to the ON posit ...

DTC/circuit diagnosis

P1610 LOCK MODE

Description

ECM forcibly switches to the mode that inhibits engine start, when engine

start operation is performed 5 times

or more while communication between ECM and BCM is not normal.

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P1610 is displayed with other DTC (for BCM or ...

Before starting the engine

Make sure the area around the vehicle is

clear.

Check fluid levels such as engine oil, coolant,

brake and clutch fluid(if so equipped),

and windshield-washer fluid as frequently as

possible, or at least whenever you refuel.

Check that all windows and lights are clean.

Visually inspe ...