Nissan Sentra Service Manual: Removal and installation

SIDE OIL SEAL

Removal and Installation

REMOVAL

- Remove front drive shafts. Refer to FAX-18, "6M/T : Removal and Installation (LH)".

- Remove differential side oil seals (1) from clutch housing and transaxle case using a suitable tool.

CAUTION:

Do not damage transaxle case and clutch housing.

INSTALLATION

Installation is in the reverse order of removal.

- Install differential side oil seals (1) to clutch housing and transaxle case, using Tools.

Tool number : KV32500QAA

Tool number : B.vi 1666-B

- Transaxle case side

- Clutch housing side

Dimension (L1) : 1.2 –≤–ā‚Äú 1.8 mm (0.047 –≤–ā‚Äú 0.071 in)

Dimension (L2) : 2.7 –≤–ā‚Äú 3.3 mm (0.106 –≤–ā‚Äú 0.130 in)

CAUTION:

- Do not incline differential side oil seal.

- Do not damage clutch housing and transaxle case.

Inspection

INSPECTION AFTER INSTALLATION

Check the oil level and oil leaks. Refer to TM-19, "Inspection".

POSITION SWITCH

Removal and Installation

REMOVAL

- Remove battery. Refer to PG-50, "Removal and Installation (Battery)".

- Disconnect position switch harness connector.

- Remove position switch from transaxle case.

INSTALLATION

- Apply recommended sealant to threads of position switch.

- Use Genuine Liquid Gasket, Three Bond 1215 or an equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

CAUTION:

Remove old sealant and oil adhering to threads.

- Install position switch to transaxle case.

- Tighten position switch to the specified torque. Refer to TM-30, "Exploded View".

- For the next step and after, install in the reverse order of removal.

Inspection

INSPECTION AFTER INSTALLATION

- Check continuity between position switch terminals. Refer to TM-17, "BACK-UP LAMP SWITCH : Component Inspection" (Back-up lamp switch) and TM-17, "PARK/NEUTRAL POSITION (PNP) SWITCH : Component Inspection" (PNP switch).

- Check the oil leaks. Refer to TM-19, "Inspection".

Control linkage

Exploded View

- Bracket

- Shifter cable

- Selector lever

- Shift lever

- Tapping bolt

- M/T cable mounting bracket

- Selector cable

- Grommet

- Shift selector assembly

- Shift selector

- Shift selector knob

Removal and Installation

Removal

- Move the shift selector to the neutral position.

- Remove air cleaner case assembly. Refer to em-25, "removal and installation".

- Remove the battery tray and battery support brackets. Refer to pg-51, "removal and installation (battery bracket)".

- Disconnect the each cable from the shifter lever a (b) and the selector lever (a) using a suitable tool.

- While pressing the lock of the selector cable in the direction of the arrow shown, remove the selector cable from the m/t cable bracket.

- While pressing the lock of the shifter cable in the direction of the arrow shown, remove the shifter cable from the m/t cable bracket.

- Remove m/t cable bracket from transaxle case.

- Remove the center console side finishers (1) (lh/rh).

- Remove the center console side finisher screw (a) (lh/rh).

- Release the clips using a suitable tool, then remove the center console side finisher.

Metal clip

Metal clip

- Remove the cvt/mt shift selector finisher (1).

- Remove cluster lid c. Refer to ip-20, "removal and installation - cluster lid c lower".

- Remove the CVT/MT shift selector screws (A).

- Release the clips using a suitable tool, then remove the CVT/MT shift selector finisher.

Metal clip

Metal clip

- Pull out and disconnect the shifter cable from the pin of the shift selector assembly using a suitable tool

- Pull up the cable stopper (a) of the selector cable in the direction of the arrow as shown.

- Pull out and disconnect the selector cable from the pin of the shift selector assembly, using a suitable tool.

- While pressing the lock of the selector cable in the direction of the arrow shown, remove the selector cable from the shift selector assembly.

- While pressing the lock of the shifter cable in the direction of the arrow shown, remove the shifter cable from the shift selector assembly.

- Remove the shift selector assembly.

- Remove the tunnel stay (1).

- Remove exhaust front tube and sub muffler. Refer to ex-5, "removal and installation".

- Remove the heat plate fixtures (A).

: Front

: Front

- Remove the shift cable and selector cable from the bracket.

- Disengage the pawls (a) of the grommet (1), and pull downwards to remove.

- Remove the shifter cable and selector cable from the vehicle.

Installation

Installation is in the reverse order of removal.

CAUTION:

- Install each cable without causing interference with other parts, a 120 mm (4.72 in)-or-less bend, and a 180-degrees-or-more twist.

- Install boot of each cable without causing interference with other parts and a 90-degrees-or-more twist.

- Fit boot of to center console assembly the groove on shift selector knob.

- To install the shift selector knob, press it into the shift selector.

CAUTION:

- Do not reuse shift selector knob.

- Be careful with orientation of shift selector knob.

- Tapping work for tapping bolts is not applied to new transaxle case. Do not perform tapping by other than screwing tapping bolts because tapping is formed by screwing tapping bolts into transaxle case.

CAUTION:

Do not reuse tapping bolt.

- Insert the each cable until it reaches the cable mounting bracket and shift selector assembly.

- Insert the each cable until it reaches the shifter lever A and the selector lever.

- Move the shift selector to the neutral position.

- Install the shifter cable (1) and the selector cable (2) to the bracket (3) as shown.

Install the selector cable (the shift selector assembly side), as per the following procedure.

When shift selector is replaced:

- Install the selector cable to the shift selector assembly.

- Move the shift selector to the neutral position.

- Install the shift selector stopper (A) to the shift selector assembly as shown.

CAUTION:

Selector cable cannot be adjusted accurately without using the shift selector stopper.

- Check that the shift selector does not move in a back and forth direction. If it moves, repeat the installation of the shift selector stopper to the shift selector assembly.

- Insert the cable stopper (A) until it reaches the selector cable.

- Remove the shift selector stopper from the shift selector assembly.

- Move the shift selector to each gear position to check that there are no bindings. If any, repeat the installation of the shift selector stopper to the shift selector assembly.

When shift selector assembly is not replaced:

- Install the selector cable to the shift selector assembly.

- Move the shift selector to the 4th gear position.

- Adjust the length (L) between the cable stopper (A) and the shift selector to the standard value.

Length (L) : 3.51 –≤–ā‚Äú 4.11 mm (0.1382 –≤–ā‚Äú 0.1618 in)

- Insert the stopper (A) until it reaches the selector cable.

- Move the shift selector to each gear position to check that there are no bindings. If any, repeat the adjustment of the length between the cable stopper and the shift selector.

Inspection

INSPECTION AFTER INSTALLATION

Shift selector Knob

Check that the shift selector knob is installed in the right position.

Shifter Cable and Selector Cable

- Pull each cable in the removal direction to check that it dose not disconnect from the cable mounting bracket.

- Pull each cable in the removal direction to check that it dose not disconnect from the shift selector assembly.

- Pull grommet in the removal direction to check that it dose not disconnect from the vehicle.

Shift Selector Assembly and shift selector

- Check that there is no tangle, hook, abnormal sound, looseness, and interference when the shifter selector is moved to each position. If there is a malfunction, then repair or replace the malfunctioning part.

- Check that the shifter selector smoothly returns to the neutral position after moving the shift selector from 1st to 2nd gear and moving hands off the shift selector. If there is a malfunction, then repair or replace the malfunctioning part.

- Check that the shift selector smoothly returns to the neutral position after moving the lever from 5th to 6th gear and moving hands off the shift selector. If there is a malfunction, then repair or replace the malfunctioning part.

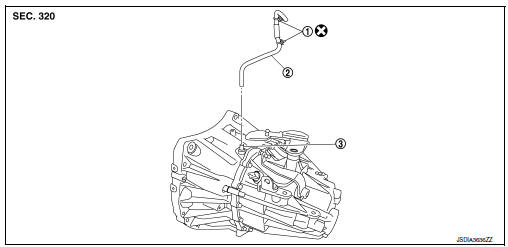

Air breather hose

Exploded View

- Clip

- Air breather hose

- 2 way connector

Removal and Installation

REMOVAL

- Remove air cleaner case assembly. Refer to EM-25, "Removal and Installation".

- Remove clips (1).

: Front

: Front

- Remove air breather hose from the 2 way connector.

CAUTION:

When removing air breather hose, be sure to hold 2 way connector securely.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Install air breather hose, preventing crush and clogging caused by bending.

- Insert the allowance of air breather hose to the spool of the 2 way connector.

- Install air breather hose to the 2 way connector with the paint mark faced forward of the vehicle.

- Securely engage the clips in the hole.

- Do not reuse clip.

Periodic maintenance

Periodic maintenance

M/T OIL

Inspection

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

OIL LEVEL

Remove filler plug (1) and gasket from transaxle case.

Check the oil level from f ...

Unit removal and installation

Unit removal and installation

TRANSAXLE ASSEMBLY

Exploded View

Transaxle assembly

Refer to INSTALLATION

Removal and Installation

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns

co ...

Other materials:

Power windows do not operate with power window main switch

Diagnosis Procedure

1.Check bcm power supply and ground circuit

Check bcm power supply and ground circuit.

Refer to bcs-67, "diagnosis procedure" (with intelligent key) or bcs-120,

"diagnosis procedure" (without

intelligent key).

Is the inspection result normal?

Yes & ...

Radio

With the ignition placed in the ACC or ON position,

press the PWR (power)/VOL (volume) knob

to turn the radio on. If you listen to the radio with

the engine not running, the ignition should be

placed in the ACC position.

Radio reception is affected by station signal

strength, distance from r ...

Ecu diagnosis information

Av control unit

Reference value

TERMINAL LAYOUT

PHYSICAL VALUES

Dtc index

Bose speaker amp

Reference value

TERMINAL LAYOUT

PHYSICAL VALUES

...