Nissan Sentra Service Manual: P0138 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/ F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the voltage is unusually high during the various driving condition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the minimum voltage of sensor is sufficiently low during the various driving condition such as fuel-cut.

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause | |

| P0138 | HO2S2 (B1) (O2 sensor circuit high voltage bank 1 sensor 2) | A) | An excessively high voltage from the sensor is sent to ECM. |

|

| B) | The minimum voltage from the sensor is not reached to the specified voltage. |

|

||

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 2 minutes.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-227, "Diagnosis Procedure".

NO-1 (  With CONSULT)>>GO TO 3.

With CONSULT)>>GO TO 3.

NO-2 ( Without CONSULT)>>GO TO 5.

Without CONSULT)>>GO TO 5.

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B

NOTE:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30°C (32 to 86°F).

- Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Make sure that “COOLANT TEMP/S” indication is more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLANT TEMP/S” indication reaches 70°C (158°F).

- Open engine hood.

- Select “HO2S2 (B1) P1146” of “HO2S2” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

- Follow the instruction of CONSULT.

NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

- Touch “SELF-DIAG RESULT”.

Which is displayed on CONSULT

OK >> INSPECTION END

NG >> Proceed to EC-227, "Diagnosis Procedure".

CAN NOT BE DIAGNOSED>>GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION B AGAIN

- Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

- Perform DTC confirmation procedure again.

>> GO TO 3.

5.PERFORM COMPONENT FUNCTION CHECK FOR MALFUNCTION B

Perform component function check. Refer to EC-226, "Component Function Check".

NOTE:

Use component function check to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-227, "Diagnosis Procedure".

Component Function Check

1.PERFORM COMPONENT FUNCTION CHECK-1

Without CONSULT

Without CONSULT

- Start engine and warm it up to normal operating temperature

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.PERFORM COMPONENT FUNCTION CHECK-2

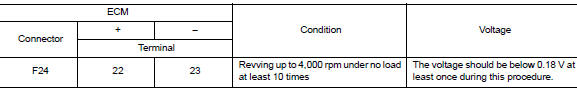

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 3.

3.PERFORM COMPONENT FUNCTION CHECK-3

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-227, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the detected malfunction (A or B). Refer to EC-225, "DTC Logic".

Which malfunction is detected? A >> GO TO 2.

B >> GO TO 6.

2.CHECK HO2S2 CONNECTOR FOR WATER

- Turn ignition switch OFF.

- Disconnect heated oxygen sensor 2 harness connector.

- Check connectors for water.

Water should not exist.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK HO2S2 GROUND CIRCUIT

- Disconnect ECM harness connector.

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK HO2S2 INPUT SIGNAL CIRCUIT

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK HEATED OXYGEN SENSOR 2

Check the heated oxygen sensor 2. Refer to EC-229, "Component Inspection (HO2S2)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

6.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

- Clear the mixture ratio self-learning value. Refer to EC-142, "Work Procedure".

- Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0172 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0172. Refer to EC-250, "DTC Logic".

NO >> GO TO 7.

7.CHECK HO2S2 GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect heated oxygen sensor 2 harness connector.

- Disconnect ECM harness connector.

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK HO2S2 INPUT SIGNAL CIRCUIT

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK HEATED OXYGEN SENSOR 2

Check the heated oxygen sensor 2. Refer to EC-229, "Component Inspection (HO2S2)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

Component Inspection (HO2S2)

1.INSPECTION START

Do you have CONSULT? Do you have CONSULT? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK HEATED OXYGEN SENSOR 2

With CONSULT

With CONSULT

- Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute

- Select “FUEL INJECTION” in “ACTIVE TEST” mode of “ENGINE” using CONSULT, and select “HO2S2 (B1)” as the monitor item with CONSULT.

- Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to ± 25%.

“HO2S2 (B1)” should be above 0.72 V at least once when the “FUEL INJECTION” is + 25%.

“HO2S2 (B1)” should be below 0.18 V at least once when the “FUEL INJECTION” is − 25%.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

3.CHECK HEATED OXYGEN SENSOR 2-1

Without CONSULT

Without CONSULT

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK HEATED OXYGEN SENSOR 2-2

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK HEATED OXYGEN SENSOR 2-3

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

P0137 HO2S2

P0137 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen

storage capacity of the three way ...

P0139 HO2S2

P0139 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen

storage capacity of the three way ...

Other materials:

Removal and installation

Starter motor

Exploded View

“S” terminal harness

“B” terminal harness

Starter motor

Cylinder block

Removal and Installation

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug

openings to prevent fluid from spilling.

REMOVAL

Dis ...

Ignition timing

Inspection

1.CHECK IGNITION TIMING

Attach timing light to the ignition coil No.1 harness.

Check ignition timing.

: Timing indicator

Specification : EC-486, "Ignition Timing"

>> INSPECTION END

...

Wiring diagram

Sport mode system

Wiring diagram

...