Nissan Sentra Service Manual: P1554 Battery current sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P1554 | BAT CURRENT SENSOR (Battery current sensor) | The output voltage of the battery current sensor is lower than the specified value while the battery voltage is high enough. |

|

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-383, "Component Function Check".

NOTE:

Use component function check to check the overall function of the battery current sensor circuit. During this check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-384, "Diagnosis Procedure".

Component Function Check

1.PRECONDITIONING

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 12.8 V at idle.

Before performing the following procedure, confirm that all load switches and A/C switch are turned OFF.

>> GO TO 2.

2.PERFORM COMPONENT FUNCTION CHECK

With CONSULT

With CONSULT

- Start engine and let it idle.

- Select “BAT CUR SEN” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Check “BAT CUR SEN” indication for 10 seconds.

“BAT CUR SEN” : above 2,300 mv at least once

Without

Without

CONSULT

- Start engine and let it idle.

- Check the voltage between ECM harness connectors.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-384, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BATTERY CURRENT SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect battery current sensor harness connector

- Turn ignition switch ON.

- Check the voltage between battery current sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Check sensor power supply 2 circuit. Refer to EC-444, "Diagnosis Procedure".

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

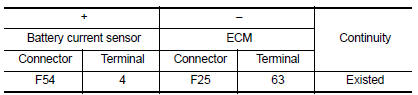

3.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector

- Check the continuity between battery current sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

- Check the continuity between battery current sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts

5.CHECK BATTERY CURRENT SENSOR

Check the battery current sensor. Refer to EC-385, "Component Inspection (Battery Current Sensor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace battery current sensor. Refer to PG-53, "Removal and Installation".

Component Inspection (Battery Current Sensor)

1.CHECK BATTERY CURRENT SENSOR

- Turn ignition switch OFF.

- Reconnect harness connectors disconnected.

- Disconnect battery negative cable.

- Install jumper cable between battery negative terminal and body ground.

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery current sensor. Refer to PG-53, "Removal and Installation".

P1553 Battery current sensor

P1553 Battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1553

BAT CURRENT SENSOR

(Battery curr ...

P1556, P1557 Battery temperature sensor

P1556, P1557 Battery temperature sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P1556 or P1557 is displayed with DTC P0643, first perform the

trouble diagnosis for DTC P0643.

Refer to EC-353, "DTC Logic".

DTC No ...

Other materials:

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

Customer interview

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any

custome ...

Dlc branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the data link connector for

damage, bend and loose connection

(connector side and harness side).

Is the inspection resul ...

Precaution for Liquid Gasket

REMOVAL OF LIQUID GASKET

After removing nuts and bolts, separate the mating surface, using Tool

and remove old liquid gasket.

Tool number : KV10111100 (J-37228)

CAUTION:

Be careful not to damage the mating surfaces.

Tap (1) Tool to insert it, and then slide it (2) by tapping on t ...