Nissan Sentra Service Manual: Trunk lid

Trunk lid assembly

Trunk lid assembly : exploded view

- Trunk lid hinge LH/RH

- Torsion bar LH/RH

- Torsion bar clips

- Trunk lid finisher (if equipped)

- Emergency release handle

- Emergency release handle clip

- Emergency release handle cable

- Trunk lid lock

- Trunk lid bumpers

- License lamp finisher

- Trunk lid

- Rear spoiler (if equipped)

- Weatherstrip

- Clip

Clip

Clip

Trunk lid assembly : removal and installation

CAUTION:

- Use two people when removing or installing trunk lid assembly due to its heavy weight.

- Use protective tape or shop cloths to protect surrounding components from damage during removal and installation of trunk lid assembly.

REMOVAL

- Remove trunk lid finisher (if equipped). Refer to INT-45, "Removal and Installation".

- Disconnect the harness connectors in the trunk lid assembly (1) and remove the harness clips (A) then pull out harness from the trunk lid assembly (1).

- Remove the bolts (A) and remove the trunk lid assembly (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, perform the trunk lid assembly adjustment procedure. Refer to DLK-185, "TRUNK LID ASSEMBLY : Adjustment".

Trunk lid assembly : adjustment

- Trunk lid assembly

- Trunk lid hinge

- Trunk lid striker

- Body side outer

- Rear combination lamp

- Reflector

- Rear bumper fascia

- Trunk lid bolts

- Striker bolts

Check the clearance and the surface height between trunk lid and each part by visual inspection and tactile feel.

If the clearance and the surface height are out of specification, adjust them according to the adjustment procedures.

LONGITUDINAL CLEARANCE

Trunk Lid Removed From Hinge

- Loosen the trunk lid to hinge bolts.

- Move the trunk lid so that the clearance measurements are within specifications provided.

- Tighten the trunk lid to hinge bolts.

Trunk Lid Hinge Removed From Vehicle

- Remove the rear parcel shelf finisher. Refer to INT-33, "Removal and Installation".

- Loosen the hinge to parcel shelf bolts.

- Move the trunk lid so that the clearance measurements are within specifications provided.

- Tighten the hinge to parcel shelf bolts

- Install the rear parcel shelf finisher. Refer to INT-33, "Removal and Installation".

SURFACE HEIGHT ADJUSTMENT

- Loosen the bumper rubber.

- Loosen the striker bolts.

- Lift up the trunk lid approx. 100 - 150 mm (3.94 - 5.91 in) height then close it lightly. Make sure it engages firmly with the trunk lid closed.

- Tighten the trunk lid striker.

Trunk lid hinge

Trunk lid hinge : removal and installation

REMOVAL

- Remove trunk lid assembly. Refer to DLK-183, "TRUNK LID ASSEMBLY : Removal and Installation".

- Remove torsion bar. Refer to DLK-187, "TORSION BAR : Removal and Installation".

- Remove rear parcel shelf finisher. Refer to INT-33, "Removal and Installation".

- Remove trunk lid hinge bolts (body side) and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Check trunk lid open/close, lock/unlock operation after installation.

- After installation, perform the trunk lid assembly adjustment procedure. Refer to DLK-185, "TRUNK LID ASSEMBLY : Adjustment".

Check trunk lid hinge rotating point for poor lubrication. If necessary, apply a suitable multi-purpose grease.

Torsion bar

Torsion bar : removal and installation

REMOVAL

- Remove torsion bar clips.

- Support the trunk lid assembly using a suitable tool.

WARNING:

Bodily injury may occur if hood assembly is not supported properly when removing hood assembly.

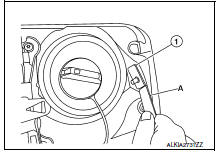

- Lift torsion bar (1) using a suitable tool (A) as shown to remove

NOTE:

The suitable tool specifications are as shown.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation check the trunk lid open/close, lock/unlock operation.

Trunk lid lock

Trunk lid lock : removal and installation

REMOVAL

- Remove the trunk lid finisher (if equipped). Refer to INT-45, "Removal and Installation".

- Disconnect the harness connector (B) and emergency release handle (2) from the trunk lid lock (1).

- Remove the trunk lid lock bolts (A) and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, perform the trunk lid assembly adjustment procedure. Refer to DLK-185, "TRUNK LID ASSEMBLY : Adjustment".

Emergency lever

EMERGENCY LEVER : Removal and Installation

REMOVAL

- Remove the trunk lid finisher (if equipped). Refer to INT-45, "Removal and Installation".

- Using a suitable tool release the pawls and remove emergency release handle (1) from trunk lid assembly.

: Pawl

: Pawl

- Disconnect emergency release handle cable (2) from trunk lid lock assembly (3).

INSTALLATION

Installation is in the reverse order of removal.

Trunk lid striker

TRUNK LID STRIKER : Removal and Installation

REMOVAL

- Remove the trunk kicking plate. Refer to INT-42, "TRUNK REAR PLATE : Removal and Installation".

- Remove bolts (A) and striker (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, perform the trunk lid assembly adjustment procedure. Refer to DLK-185, "TRUNK LID ASSEMBLY : Adjustment".

Fuel filler lid opener

Exploded view

- Fuel filler lid

- Bumper rubber

- Fuel filler lid opener cable

- Fuel filler lid lock

- Clip

- Bolt

- Cable protector

Fuel filler lid

Fuel filler lid : removal and installation

REMOVAL

- Fully open fuel filler lid.

- Remove fuel cap clip (A).

- Remove fuel filler lid screws (A) and fuel filler lid (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, check fuel filler lid assembly open/close, lock/unlock operation.

NOTE:

- The following table shows the specifications for a correctly installed fuel filler lid.

- Fitting adjustment cannot be performed.

Fuel filler opener cable

FUEL FILLER OPENER CABLE : Removal and Installation

REMOVAL

- Remove hood and fuel filler handle assembly bolts (A).

- Release fuel filler lid opener cable (2) by pulling downward and then sliding cable end to the side to remove from hood and fuel filler handle assembly (1).

- Remove dash side finisher (LH). Refer to IP-14, "Removal and Installation".

- Remove center pillar lower finisher (LH). Refer to INT-27, "CENTER PILLAR LOWER FINISHER : Removal and Installation".

- Remove rear seat bolster (LH). Refer to SE-24, "Removal and Installation - Rear Seat Bolster".

- Remove trunk side finisher (LH). Refer to INT-43, "TRUNK SIDE FINISHER : Removal and Installation".

- Remove fuel filler lid opener cable (1) from fuel filler lid lock assembly. Refer to DLK-192, "FUEL FILLER LID LOCK : Removal and Installation".

Front

Front

- Remove each cable protector (A), then remove fuel filler lid opener cable (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, check fuel filler lid assembly open/close, lock/unlock operation.

Fuel filler lid lock

Fuel filler lid lock : removal and installation

REMOVAL

- Fully open fuel filler lid.

- Insert a suitable tool (A) as shown into bottom of fuel filler lock assembly(1).

- Release upper and lower pawls (A) using a suitable tool and remove fuel filler lid lock assembly (1).

CAUTION:

Be careful not to damage gasket (2) when removing.

- Disconnect fuel filler lid opener cable (1) by pulling downward and then sliding cable end to the side to remove from fuel filler lid lock assembly (2).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, check fuel filler lid assembly open/close, lock/unlock operation.

Door switch

Removal and installation

REMOVAL

- Remove the door switch screw (A).

- Disconnect the harness connector from the door switch (1) and remove.

INSTALLATION

Installation is in the reverse order of removal.

Door handle

Door handle

Front door handle

Front door handle : exploded view

Outside handle bracket

Front gasket

Outside handle

Intelligent key button

Door key cylinder rod

Inside handle assembly

Rear ga ...

Inside key antenna

Inside key antenna

Console

CONSOLE : Removal and Installation

REMOVAL

Remove the shift selector finisher. Refer to IP-17, "Removal and

Installation".

Remove the inside key antenna (console) screws (A ...

Other materials:

Spark plugs

Replacing spark plugs

WARNINGBe sure the engine and ignition switch are

off and that the parking brake is engaged

securely.

CAUTION

Be sure to use the correct socket to remove

the spark plugs. An incorrect socket

can damage the spark plugs.

Platinum-tipped spark plugs (ex ...

BCM branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the bcm for damage, bend and loose

connection (unit side and

connector side).

Is the inspection result normal?

Yes > ...

System

Meter system

Meter system : system diagram

Meter system : system description

COMBINATION METER

The combination meter receives signals from switches, sensors and modules to

control the following functions:

Speedometer/tachometer

Warning lamps

Indicator lamps

Meter illumination c ...